ScrapperPt

Member

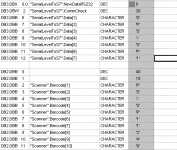

I have a scanner that i need to gather the barcode for my plc of a certain material. I have a S7 Winac rtx soft-plc on the machine. Usually for that i buy a SSI card and a Et200s to get the com port. And place a small cabinet to hold that electronics, but it is an expensive solution for a 100$ cordless scanner.

The scanner has a 20meter range from the docking station. So i could, easily connect the docking station to the IPC running winac rtx and use the comm port of the scanner. I can see the codes by using the hyperterminal. But the blocks don't seem to work even if i configure COM port 1.

Does anybody know how i can do this?

The scanner has a 20meter range from the docking station. So i could, easily connect the docking station to the IPC running winac rtx and use the comm port of the scanner. I can see the codes by using the hyperterminal. But the blocks don't seem to work even if i configure COM port 1.

Does anybody know how i can do this?