jrowe4

Member

I have a question regarding PID scaling on a PLC5. I have a cascade PID loop setup where a dryer's outlet air temperature controls an inlet air temperature.

My outlet air temperature PV range is scaled from 0-200 C. and my inlet air temperature PV range is scaled from 0-400 C. However, the issue is that my burner can not achieve a range of 400 C. Simply, I want to adjust the scaling.

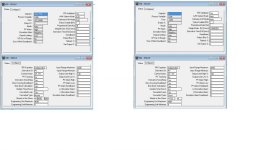

I am achieving my current temperature ranges by scaling type J thermocouple data into 0-4095 for use by the PID blocks. For example, I am scaling the outlet air by 20.475 and the inlet air by 10.2375 to put both into the range 0-4095 (shown in the scaling.jpg attachment).

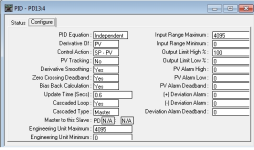

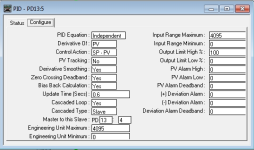

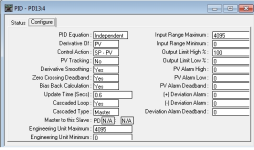

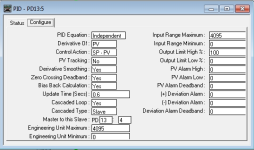

I am using type PD PID blocks set up for cascade mode. I am also using 0-4095 respectively in the engineering unit min and max parameters (shown in the master/slave.jpg attachement).

I want to change the outlet air scaling to 0-150 C. and the inlet air scaling to 0-250C. Would I just have to pick new scaling factors (the 20.475 and 10.2375) to get my new ranges or do I need to mess around with the engineering unit min and max parameters?

It would be nice to work with EU instead of raw data, but I feel I would get the same results either way. I am not sure if my way of thinking is correct, so I turn to the experts on this stuff. Thanks for any help you can offer, I appreciate it!

My outlet air temperature PV range is scaled from 0-200 C. and my inlet air temperature PV range is scaled from 0-400 C. However, the issue is that my burner can not achieve a range of 400 C. Simply, I want to adjust the scaling.

I am achieving my current temperature ranges by scaling type J thermocouple data into 0-4095 for use by the PID blocks. For example, I am scaling the outlet air by 20.475 and the inlet air by 10.2375 to put both into the range 0-4095 (shown in the scaling.jpg attachment).

I am using type PD PID blocks set up for cascade mode. I am also using 0-4095 respectively in the engineering unit min and max parameters (shown in the master/slave.jpg attachement).

I want to change the outlet air scaling to 0-150 C. and the inlet air scaling to 0-250C. Would I just have to pick new scaling factors (the 20.475 and 10.2375) to get my new ranges or do I need to mess around with the engineering unit min and max parameters?

It would be nice to work with EU instead of raw data, but I feel I would get the same results either way. I am not sure if my way of thinking is correct, so I turn to the experts on this stuff. Thanks for any help you can offer, I appreciate it!