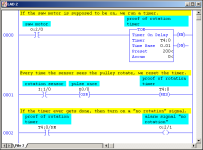

Hello. I am a novice at plc programming and am trying to achieve the following goal. I have an input from a sensor to detect the rotation of the idler wheel on a bandsaw. The input switches on to off at an irregular rate. I wish to control the state of a bit to tell when the rotation has stopped. Any recommendations for the most efficient way to accomplish this task? I am working in RS500.

Last edited: