Hi folks

I received an AB 820 micro from a friend who is an electromechanical wizard but was so frustrated trying to program it that he gave it to me and said "see if you can figure it out"

I had never seen a PLC before last week, but I have been obsessed with this thing since he brought it here.

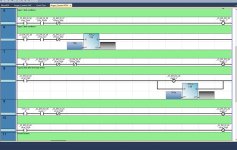

He wants to have a door open when a limit switch is triggered by a feed cart and auger motors fired up. First the auger outside the door to clean it out and then 5 seconds later fire up the internal auger behind the door to continue loading the outside auger. There is a load limit switch on the outside auger, to prevent it from overflowing in case of a jam, that needs to pause the inside auger for about 15s while the outside auger keeps running to clear the load.

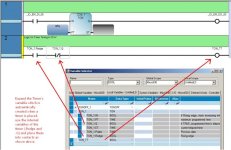

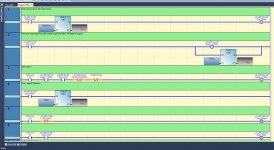

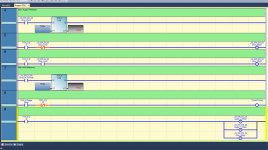

There is a start sequence for both augers on this rung(rung 6) that I don't want to run if the 15s delay timer in the earlier rung (rung 2)is active.

I thought I could use a TON timer bool bit from TON10 to indicate to rung 6 that the timer on rung 2 is active but it doesn't seem to be working for me. I have tried contacts/reverse contacts pointing to the IN and the Q but it doesn't seem to matter... the timer is ignored and the rung 6 is true every pass. Feel free to point out as much of my ignorance as you can

As an aside can anyone recommend the best book I should buy to start out with? Or a good online training course. I have gotten this far by reading whatever resources I can find online but there doesn't seem to be a lot of stuff for CCW.

Thanks for all and any input for this absolute neophyte.

Mongoid

I received an AB 820 micro from a friend who is an electromechanical wizard but was so frustrated trying to program it that he gave it to me and said "see if you can figure it out"

I had never seen a PLC before last week, but I have been obsessed with this thing since he brought it here.

He wants to have a door open when a limit switch is triggered by a feed cart and auger motors fired up. First the auger outside the door to clean it out and then 5 seconds later fire up the internal auger behind the door to continue loading the outside auger. There is a load limit switch on the outside auger, to prevent it from overflowing in case of a jam, that needs to pause the inside auger for about 15s while the outside auger keeps running to clear the load.

There is a start sequence for both augers on this rung(rung 6) that I don't want to run if the 15s delay timer in the earlier rung (rung 2)is active.

I thought I could use a TON timer bool bit from TON10 to indicate to rung 6 that the timer on rung 2 is active but it doesn't seem to be working for me. I have tried contacts/reverse contacts pointing to the IN and the Q but it doesn't seem to matter... the timer is ignored and the rung 6 is true every pass. Feel free to point out as much of my ignorance as you can

As an aside can anyone recommend the best book I should buy to start out with? Or a good online training course. I have gotten this far by reading whatever resources I can find online but there doesn't seem to be a lot of stuff for CCW.

Thanks for all and any input for this absolute neophyte.

Mongoid