Thunderbike

Member

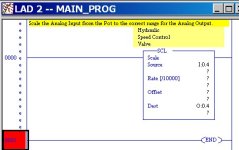

Ihave a machine with a failed Moeller PLC that I have no documented logic for, and am replacing with a micrologix 1000 1761-L20BWB-5A. Most of my experience with RSlogix (and other programs) is in diagnose, repair and minor tweaking of machines. I have written most of the required logic I need on this 1000 using the simple drag and drop "user" menu. I now have to set up the analog portion and am flat out lost! I have a hyd valve that controls speed using 0-10V input. There was a 20K pot used as an analog input, and the output controlled the valve. I am totally in the dark, and dont even know how to find or address the analog inputs and output. could someone walk me thru this PLEASE? this is soooo much different than the SLC 500 I'm used to working with.

thanks

thanks