kasch try this.

copy the text below and save so you can find it.

Open a new instance of Direct Soft, click on file, import program, find the file you just saved and follow directions.

Copy below this line

PLC 05

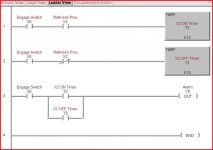

// Rung 1

// Address 0

#BEGIN COMMENT

"http://www.plctalk.net/qanda/showthread.php?p=610753#post610753"

""

"I am using DirectSOFT 5 to create a program, with a one shot, and a timer on delay to "

"turn on the alarm when the timer runs out, but can not figure out the correct way to lay out "

"the program. The software will not let me insert the one shot in the middle of the rung? "

"Can someone please help by drafting up a program to do this?"

""

"Sounds like you have some RS logix experience. Direct Soft uses a different approach for "

"oneshots. Here is one of them. Note the PD coil."

""

""

#END

STR X1

PD C0

// Rung 2

// Address 2

#BEGIN COMMENT

"This rung is to check if the timer is done (not) and the prox OS were active at the same "

"time. If the conditions are true then we have a need to un sealin the alarm bit for the "

"rethresh prox"

""

"Note: the placement of this rung is scan critical it needs to be between the OS output and "

"the timer"

#END

STRN T0

AND C0

OUT C10

// Rung 3

// Address 5

STRN C0

AND X0

TMRF T0 K13

// Rung 4

// Address 10

#BEGIN COMMENT

""

""

#END

STR X2

PD C1

// Rung 5

// Address 12

#BEGIN COMMENT

"This rung is to check if the timer is done (not) and the prox OS were active at the same "

"time. If the conditions are true then we have a need to un sealin the alarm bit for the "

"rethresh prox"

""

"Note: the placement of this rung is scan critical it needs to be between the OS output and "

"the timer"

#END

STRN T1

AND C1

OUT C11

// Rung 6

// Address 15

#BEGIN COMMENT

"When I calculate the speed of the shaft prox 19.04761904761905 mseconds per "

"revolution it appears that you will just barely be able to sense the high speed shaft. As "

"Lancie mentioned you will need to have the prox on time be equal to the off time. This "

"would mean that the nominal on time would be 9.5 mseconds. As long as the PLC scan "

"time does not exceed 4 mseconds you should be able to sense every revolution. "

""

"One issue might be that the coarseness of the TMRF, it only goes to 10 msecond "

"resolution (0.01 seconds) and scan time. If I have calulated the time per revolution "

"correctly and your scan time was 4 mseconds the worst case senario would be the shaft "

"speed could drop to 2516 rpm before an alarm is triggered. Best case would be it could "

"drop to 3000 RPM before an alarm is triggered. "

#END

STRN C1

AND X0

TMRF T1 K1

// Rung 7

// Address 20

#BEGIN COMMENT

"This is one way to deal with the issue (sealin) that Lancie mentioned. "

#END

STR T0

STR C2

ANDN C10

ORSTR

OUT C2

// Rung 8

// Address 25

#BEGIN COMMENT

"This is one way to deal with the issue (sealin) that Lancie mentioned. "

#END

STR T1

STR C3

ANDN C11

ORSTR

OUT C3

// Rung 9

// Address 30

#BEGIN COMMENT

"This rung will sound an alarm and silence it untill there is a new alarm"

#END

STRPD C2

ORPD C3

ANDN X3

OUT Y0

// Rung 10

// Address 34

END

// Rung 11

// Address 35

NOP

#BEGIN ELEMENT_DOC

"X0","EngageSw","",""

"X1","RetreshProx","",""

"X2","HighSpeedShaftPr","",""

"X3","AlarmSilence","",""

"Y0","alarm","",""

"C0","RetreshProx_OS","",""

"C1","HighSpeed_OS","",""

"C2","Retresh_Sealin","",""

"C3","HS_Sealin","",""

"C10","ReTMRNotandOS","","Rethresh Prox Timer (not) and OS"

"C11","HS_TMRNotandOS","","HS Prox Timer (not) and OS"

"T0","RetreshShaftTime","",""

"T1","HS_ShaftTimer","",""

#END