Hi all,

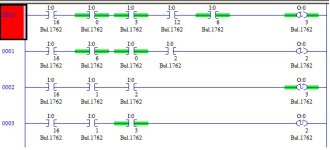

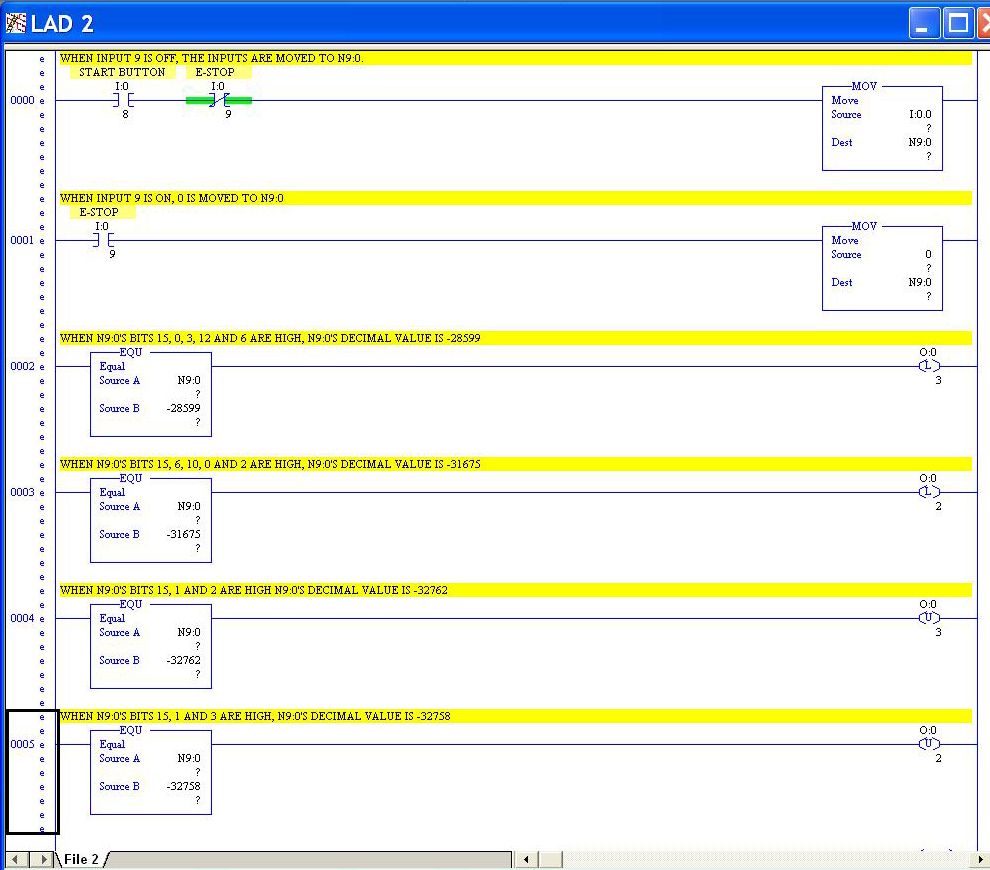

I am programming a Micrologix 1200 to run an assembly machine for my business. This is my first experience programming a PLC and this forum has been invaluable in getting the machine up and running. My program uses output latch/unlatch commands to control pneumatic solenoid valves but I have read here these are generally not the preferred commands for what I'm doing. I also don't like how their retentive nature causes the air cylinders to move to their previous location when restarting after hitting the e-stop. I would rather they go back to the home position. I have been unsuccessful finding an alternative approach, however, and could use some help.

One of the main machine actions uses two air cylinders and two associated solenoid valves to move a metal bar. One cylinder moves the bar up and down while the other moves the bar left and right. The mechanism essentially draws a square with the bar. From the home position (lower left corner of square):

Energize output 3 (move bar up)

Energize output 2 (move bar right)

De-energize output 3 (move bar down)

De-energize output 2 (move bar left)

Repeat

This portion of the current program is attached. Any input on a better approach to the programming would be greatly appreciated. My knowledge of ladder logic is generally limited to examine if open/closed, output latch/unlatch, timers, and subroutines, so I'll need a little more detailed explanation than the more experienced programmers here.

Thanks,

Jeff

I am programming a Micrologix 1200 to run an assembly machine for my business. This is my first experience programming a PLC and this forum has been invaluable in getting the machine up and running. My program uses output latch/unlatch commands to control pneumatic solenoid valves but I have read here these are generally not the preferred commands for what I'm doing. I also don't like how their retentive nature causes the air cylinders to move to their previous location when restarting after hitting the e-stop. I would rather they go back to the home position. I have been unsuccessful finding an alternative approach, however, and could use some help.

One of the main machine actions uses two air cylinders and two associated solenoid valves to move a metal bar. One cylinder moves the bar up and down while the other moves the bar left and right. The mechanism essentially draws a square with the bar. From the home position (lower left corner of square):

Energize output 3 (move bar up)

Energize output 2 (move bar right)

De-energize output 3 (move bar down)

De-energize output 2 (move bar left)

Repeat

This portion of the current program is attached. Any input on a better approach to the programming would be greatly appreciated. My knowledge of ladder logic is generally limited to examine if open/closed, output latch/unlatch, timers, and subroutines, so I'll need a little more detailed explanation than the more experienced programmers here.

Thanks,

Jeff