Davek0974

Member

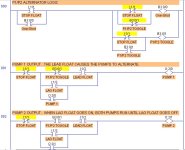

Could someone suggest a bit of code that would create a flip-flop control for a pneumatic cutter system please, couldn't find much in search so maybe its not called that?

I have the following...

cutter air valve,

cutter sensor - home,

cutter sensor - out,

the cutter works both ways - home direction and out direction so to save time and wear it parks at the out position as well as the home position while running non-stop.

I have tried a couple of ideas but once triggered they seem to get stuck in a loop.

many thanks

I have the following...

cutter air valve,

cutter sensor - home,

cutter sensor - out,

the cutter works both ways - home direction and out direction so to save time and wear it parks at the out position as well as the home position while running non-stop.

I have tried a couple of ideas but once triggered they seem to get stuck in a loop.

many thanks