No, you did not get out of date gear.

The software is obviously Cx-Programmer, probably version 4.01 (the latest).

When selecting a function, you can click on "detail" and a selection screen will pop up. You can select the required function and fill in the form.

Most of us regular users love the typing box as it saves time. Just type in what you want, as you found out. Save a heap of time if you know what you want to do.

The detail button is handy for some of the more powerful PLCs as there are about 400 odd functions and we cannot remember them all. Old timers disease. It is great to be able to type in > D2010 #37, for example. This is a compare (symbol maths) that checks to see if the value in DM2010 (register) is greater than 37. The # indicates a BCD value.& indicates a binary value.

You can set up the program the way you want it to look and work by going to "Tools" at the top of the page and selecting "options" or "keyboard mapping". You can then map short cut keys to perform commonly used functions, change the look and feel of the package, change fonts etc etc. Very powerful tool once you are used to it.

I might add that I write a lot of code in a year and find Cx-Programmer the best software for development of programs that I have used, by far. No drag and drop or any of that nonsense just good, practical fast function keys. For example, I map a normally open contact to F2. Press F2 and type in the contact number I require. If I wish to use input 0000.01, I just type in "1" and the program does the rest for me. No nonsense with rack numbers, slot numbers, I, Q, X, Y, or %, just a number. Think of the larger PLCs as a huge meory area of numbers. You use them as you wish.

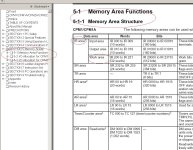

In the larger PLCs you will find addressing a little confusing at first. I use the CJ1 and CS1 all the time. I can, for example, start the first rack at channel 1500, or leave it at the default of channel 0. The point is that I get to choose where I wish to map my I/O.

Say I select default of channel 0, the first input card ia a 16 bit card and uses channel 00000, bits 00000.00 to 00000.15. The next card is a 32 bit output card. It will use channels 00001 and 00002, bits 00 to 15. The next card is a 64 bit input card. It will use channels 00003 to 00006, bits 00 to 15. If I wish to address the first channel bit 10 of the 64 bit card, I just type in the number 310, the program does the rest. The next card is an analogue input card. It will default to starting channel 2000, but I can allocate a different channel number as the starting channel for the card. The card will then use the next 10 channels. Very flexible.

I do not believe that you have made the wrong choice. the software is extremely powerful, flexible and programmable. The PLCs available go up to the latest very fast processors with an enormous array of functions and I/O capability to make life easier. They are competitively priced, although not the cheapest. You have a very long learning curve with any brand of PLC if you have only programmed smart relays. They are fine for what they are designed to do but are necessarily very limited in their capabilities.

The CPM1A is the simplest of the Omron real PLCs and is a good starting place for you to learn. It has fixed I/O allocations. One of the great things about this PLC is that it is not crippled, as are many other brands of micro PLC, by a lack of online programming functionality. I refuse to buy any PLC that does not have online programming available. They make commissioning a nightmare and very slow, quite frankly. Make a program change, stop the PLC, download the changed program, start the PLC. PAIFULL. I have used the Schneider Twido, for example. Great concept, AWFUL software and no online programming. The AB Micrologix has better software, although not as good as CX-Programmer, but NO online programming. I have dismissed both of these from my list of PLCs until they introduce online programming.

I also refuse to use the European style "drag and drop" nonsense, if given a choice. Do not intend to get RSI from clicking a "B*****" mouse. Function keys are far faster, easier to use and easier on the wrist by miles. No function keys, no use program.

Another thing to mention is if you have CX-Programmer, it will program ALL the modern Omron PLCs, with the exception of the smart relay. You do not even need software for that, just use the buttons on the front panel. No extra cost involved, no having to pay out HUGE bucks for another program because you wish to use a different PLC in a particular brand. The only exception to the rule, at this stage, is a separate set of software for the function block PLC. This is starting to be incorporated in the next revision of CX from all reports. By the way, networking etc is also incorporated in the CX program. Controller Link, Ethernet etc connectivity all built in. No extra to pay.

Welcome to the world of real PLCs. I am sure you will enjoy it as you become more proficient.

By the way, here is a link to a good learning site for Omron PLCs. The PLC disussed is the CPM1A. Enjoy.

Omron CPM1A Training