sigshane

Member

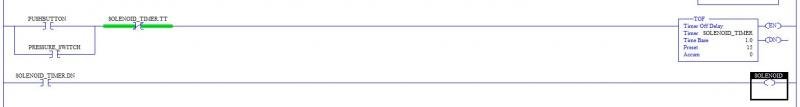

Hello all. I am trying to create an instruction that will do the following function:

When the input from either a momentary pushbutton OR a differential pressure switch becomes TRUE, immediately energize a solenoid coil, and keep it energized for 15 seconds, REGARDLESS of state of input. (This is because the pushbutton will first turn input TRUE then FALSE when it is released, but the pressure switch will keep the input TRUE until the differential is eliminated).

I have made several attempts, but they all end up having the same problem, which is how to trigger an OFF timer by turning input TRUE, then instantly turning it FALSE to start the timed output. The diff press switch being maintained is my obstacle, I think.

Shane

When the input from either a momentary pushbutton OR a differential pressure switch becomes TRUE, immediately energize a solenoid coil, and keep it energized for 15 seconds, REGARDLESS of state of input. (This is because the pushbutton will first turn input TRUE then FALSE when it is released, but the pressure switch will keep the input TRUE until the differential is eliminated).

I have made several attempts, but they all end up having the same problem, which is how to trigger an OFF timer by turning input TRUE, then instantly turning it FALSE to start the timed output. The diff press switch being maintained is my obstacle, I think.

Shane