Freebird01

Member

Ok first off this forum is great! tons of info...

I am a 3d CAD guy/machine designer by trade. I have been working on designing industrial machines for the better part of 10 years and know a little about plc's and their components to be dangerous. I have always been fascinated by the programming end of things and recently decided to take the plunge and trying to learn this.

The Automation direct stuff was had cheaply on ebay as well a some other components. As a primer into this world, I built a controller to piggy back on a manual style tubing bender. I will be converting it to a hydraulic ram with a solenoid valve to control up and down motion. I purchased a 360ppr incremental encoder from ebay (chinese but hey it should work fine for now).

The idea is i want to be able to tell the plc what angle i want to bend to...let it cycle the cylinder and use an encoder to tell it where to stop and start. I will have limit switches for homing the encoder and im running a EZ-text panel for manual inputs.

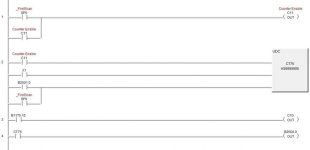

I am figuring out the inputs/outputs well enough but what has be baffled right now is getting the plc to recognize the encoder and just give me live playback to my lcd panel. as in i turn the encoder shaft by hand and have it display the angle on the LCD and be able to hit a button for reset.

i tried inputing the logic thats on this website directly and im getting nothing...

http://quantumdevices.wordpress.com/2010/04/19/optical-encoder-pulse-counting-with-a-plc/

What am I missing??? I know i have to output to a bit so the lcd panel can retrieve it and display it...please forgive me if this seems like a dumb question... my head is still spinning lol. any help would be appreciated.

I am a 3d CAD guy/machine designer by trade. I have been working on designing industrial machines for the better part of 10 years and know a little about plc's and their components to be dangerous. I have always been fascinated by the programming end of things and recently decided to take the plunge and trying to learn this.

The Automation direct stuff was had cheaply on ebay as well a some other components. As a primer into this world, I built a controller to piggy back on a manual style tubing bender. I will be converting it to a hydraulic ram with a solenoid valve to control up and down motion. I purchased a 360ppr incremental encoder from ebay (chinese but hey it should work fine for now).

The idea is i want to be able to tell the plc what angle i want to bend to...let it cycle the cylinder and use an encoder to tell it where to stop and start. I will have limit switches for homing the encoder and im running a EZ-text panel for manual inputs.

I am figuring out the inputs/outputs well enough but what has be baffled right now is getting the plc to recognize the encoder and just give me live playback to my lcd panel. as in i turn the encoder shaft by hand and have it display the angle on the LCD and be able to hit a button for reset.

i tried inputing the logic thats on this website directly and im getting nothing...

http://quantumdevices.wordpress.com/2010/04/19/optical-encoder-pulse-counting-with-a-plc/

What am I missing??? I know i have to output to a bit so the lcd panel can retrieve it and display it...please forgive me if this seems like a dumb question... my head is still spinning lol. any help would be appreciated.