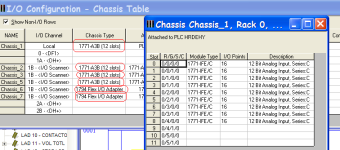

How do I Identify I/O cards in the PLC 5

- Thread starter showshocka

- Start date

Similar Topics

I received an email from a student with the following code attached. This is supposed to control a floodgate system, and supposed to be written...

Hey All.

I am working on my home automation system (again). I want to tinker around with my irrigation system.

The system itself is pretty...

I have a CompactLogix 5280 a I am trying to figure out which of the Ethernet ports are A and B. Not finding it in the manual and this is a new...

I have a project I am designing a quote for an upgrade on.

Per the schematic, the PLC I saw and an upload I took, it is run by an AB MicroLogic...

I have a Versapro project file for a Versamax PLC. Need to identify what type of variables are suitable and made available for BMS system to...