beinganmeisfun

Member

This is for a class project. Seems to be simple, but I feel I may be overthinking it.

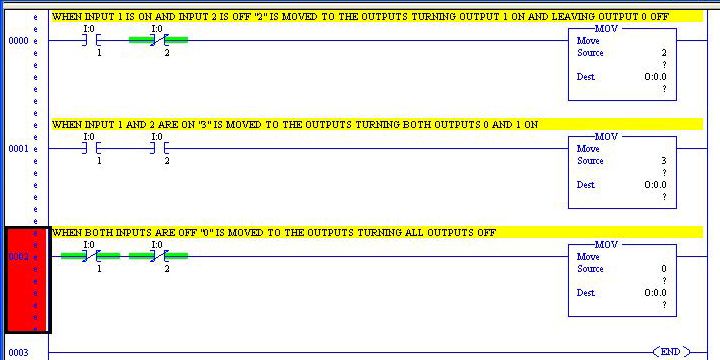

My conveyor motor is controlled by two outputs.

O:0/2 turns the motor in the forward direction.

O:0/1 (relay) and O:0/2 turn the motor on in the revere direction.

Say I wanted to do this...

I:0/1 turns on O:0/2

I:0/2 turns on O:0/2 and O:0/1

How would this be written in Logix500 so that I can change directions?

Thanks for any and all help!!

My conveyor motor is controlled by two outputs.

O:0/2 turns the motor in the forward direction.

O:0/1 (relay) and O:0/2 turn the motor on in the revere direction.

Say I wanted to do this...

I:0/1 turns on O:0/2

I:0/2 turns on O:0/2 and O:0/1

How would this be written in Logix500 so that I can change directions?

Thanks for any and all help!!

Last edited: