RJC

Member

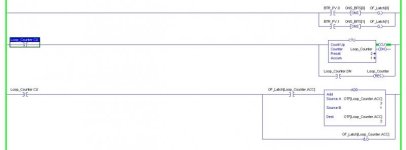

Here is the rungs I have made for my school project:

Basically I just press an associated Function Key (F1, F2, etc) on the PanelView to increase an Integer by 1 before sending it back to the PanelView's display screen.

All the tags are in order and go from 0 to 9

I would like to clean up the code if I could. . .

Is there a way to do this kind of functionality with less rungs?

I did some digging for a range or length option, but couldn't find anything

---

Other Info:

---

I may also have a follow up question as once an order is filled I need to keep a short history of previous orders

Ultimately I'm trying to avoid 50 separate move commands as I need to shift 9 Integers of data from one row to the next on the PanelView screen

I'd like to keep all the logic on the PLC if I could, but I am using an old Allen Bradley PanelView1000 Color /w Keypad if that comes into play

Talk between the two is being down via block transfer and an RIO card

Thanks ahead of time

-Ryan

Basically I just press an associated Function Key (F1, F2, etc) on the PanelView to increase an Integer by 1 before sending it back to the PanelView's display screen.

All the tags are in order and go from 0 to 9

I would like to clean up the code if I could. . .

Is there a way to do this kind of functionality with less rungs?

I did some digging for a range or length option, but couldn't find anything

---

Other Info:

---

I may also have a follow up question as once an order is filled I need to keep a short history of previous orders

Ultimately I'm trying to avoid 50 separate move commands as I need to shift 9 Integers of data from one row to the next on the PanelView screen

I'd like to keep all the logic on the PLC if I could, but I am using an old Allen Bradley PanelView1000 Color /w Keypad if that comes into play

Talk between the two is being down via block transfer and an RIO card

Thanks ahead of time

-Ryan