hi all

i am gathering some info for my little project and i am absolutely have no experience in electronics.

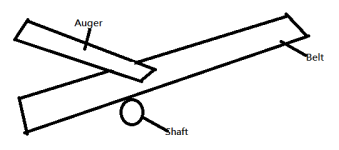

I would like to monitor a shaft(runs on AC) and if it is running then it triggers another motor(runs on AC). However I don't know what kind of sensor to use given that I cannot modify the exisiting system. All I have is a shaft.

I found I may possibly use a Hall effect sensor but I am not sure what type of Hall effect sensors is applicable as there are unipolar,bipolar,linear,latch and etc sensors.

I am thinking maybe any of them will do the job if the PLC(s7-1200) monitor the input values, say if the input changes from time to time in the last 5 seconds, then the shaft is running?

Any help is greatly appreciated.

Thanks

i am gathering some info for my little project and i am absolutely have no experience in electronics.

I would like to monitor a shaft(runs on AC) and if it is running then it triggers another motor(runs on AC). However I don't know what kind of sensor to use given that I cannot modify the exisiting system. All I have is a shaft.

I found I may possibly use a Hall effect sensor but I am not sure what type of Hall effect sensors is applicable as there are unipolar,bipolar,linear,latch and etc sensors.

I am thinking maybe any of them will do the job if the PLC(s7-1200) monitor the input values, say if the input changes from time to time in the last 5 seconds, then the shaft is running?

Any help is greatly appreciated.

Thanks