Hello. I am a student doing an independent study on PLCs. I am using a Allen Bradley SLC 5/02. What I am trying to accomplish is to step a simple pneumatic robot through 9 steps that would control its operation. Me and my partner started out with just the sequencer and a simple program to make sure everything was working. Once we were able to control the robot using the sequencer and a PBNO we attempted to control it using timers.

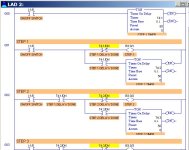

I tried cascading the timers and set up the EN bit to trip the sequencer. In my head each timer should have gone off and the EN bits would have stepped the sequencer through each step. The problem I ran into with this is that the timers would go off and nothing would happen. I tried to solve this by having each substantial timer turn off the previous one. This just created a recycle timer (which worked), but it isn't stepping through the way we need it to. I would just settle with the recycle timer, but each step needs a different time.

I apologize for the long winded explanation I hope it is clear and will gladly provide more information if needed. I appreciate your help.

I tried cascading the timers and set up the EN bit to trip the sequencer. In my head each timer should have gone off and the EN bits would have stepped the sequencer through each step. The problem I ran into with this is that the timers would go off and nothing would happen. I tried to solve this by having each substantial timer turn off the previous one. This just created a recycle timer (which worked), but it isn't stepping through the way we need it to. I would just settle with the recycle timer, but each step needs a different time.

I apologize for the long winded explanation I hope it is clear and will gladly provide more information if needed. I appreciate your help.