TL140

Lifetime Supporting Member

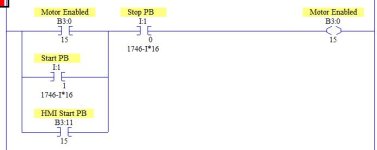

I was reading Programmable Logic Controllers: An Emphasis on Design and Application, By Kelvin T. Erickson (great book, highly recommend) and I remember that there was a section saying that the following situation was bad programming practice, but I cannot remember the solution. I wont have my book back for a few weeks and I thought that you guys may also have your own approaches so I figured why not ask you guys.

Situation:

Basic On/Off motor w/ memory with also an HMI start button. Logic would look a lil like this..

What would you guys use?

Situation:

Basic On/Off motor w/ memory with also an HMI start button. Logic would look a lil like this..

Start Stop M1

--| |-----------------| |---------( )

HMI_Start |

--| |--------|

M1 |

--| |--------|

What would you guys use?