Hi,

I have a doubt in High speed sorting systems, i want to know what is the best way for high speed sorting of a tiny object as 2 cm.

The system has continuous flow of objects , i need to classify into two different categories, i determine the category by scanning the product with camera imaging and mat lab processing.

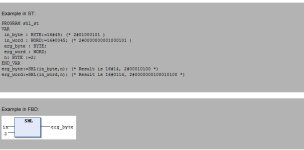

If i use timer which calculates the time product takes to reach from camera to end of conveyor, if its of A category i need to blow of and if its B category i need not blow off. How do i tackle this problem when i have a pretty high speed of products moving conveyor. if i use timers , then i need so many timers and have to reset them n no. of times.

Even I have a sensor at the end of conveyor which can detect the presence of object.

Please give your suggestion on this problem

I have a doubt in High speed sorting systems, i want to know what is the best way for high speed sorting of a tiny object as 2 cm.

The system has continuous flow of objects , i need to classify into two different categories, i determine the category by scanning the product with camera imaging and mat lab processing.

If i use timer which calculates the time product takes to reach from camera to end of conveyor, if its of A category i need to blow of and if its B category i need not blow off. How do i tackle this problem when i have a pretty high speed of products moving conveyor. if i use timers , then i need so many timers and have to reset them n no. of times.

Even I have a sensor at the end of conveyor which can detect the presence of object.

Please give your suggestion on this problem

Last edited: