Hi all,

I need some help fixing an ongoing issue I’m having that involves the 1746-HSTP1 stepper module.

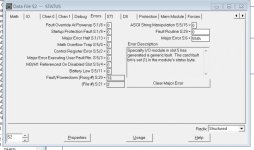

The equipment randomly shuts down due to a the PLC faulting and I’m not sure why. The 5/03 PLC shows that there is a major error halt and the error description states: “Specialty I/O module in slot 5 has generated a generic fault. The card fault bit is set (1) in the module’s status byte.” I haven’t been able to catch this in action and not sure what’s causing it.

The operators just run the machine, pushing buttons on the HMI and it happens. Silly question: Could the faults be caused by the operators hitting the buttons too fast? Could it be loose wires, lack of feedback from the motor? I have attached a snippet of the errors tab in the PLC. Maybe it can shed some light on my issue.

Thanks.

I need some help fixing an ongoing issue I’m having that involves the 1746-HSTP1 stepper module.

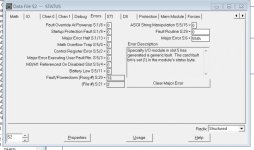

The equipment randomly shuts down due to a the PLC faulting and I’m not sure why. The 5/03 PLC shows that there is a major error halt and the error description states: “Specialty I/O module in slot 5 has generated a generic fault. The card fault bit is set (1) in the module’s status byte.” I haven’t been able to catch this in action and not sure what’s causing it.

The operators just run the machine, pushing buttons on the HMI and it happens. Silly question: Could the faults be caused by the operators hitting the buttons too fast? Could it be loose wires, lack of feedback from the motor? I have attached a snippet of the errors tab in the PLC. Maybe it can shed some light on my issue.

Thanks.