ceilingwalker

Lifetime Supporting Member

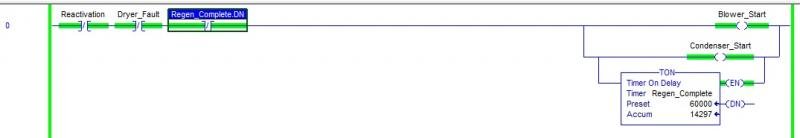

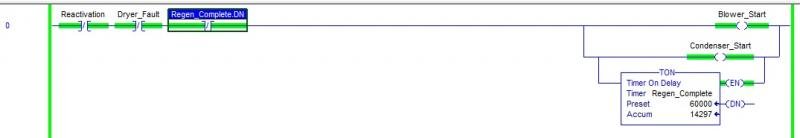

Hello. I have a question about a timer function in RSL5000 please. I have attached a screenshot of my question. In the rung shown, why is it that when Regen_Complete timer accumulator equals the preset, the timer doesn't stop? This is a rung taken from an actual program that is running, I just wanted to test it by itself because the results weren't making sense to me. I don't think this is exactly how I would have designed this timer, I am troubleshooting what I have. The real problem with this in real life is that the system doesn't step-through and go to the cooling cycle and as long as everything is left alone, it will run heat from now until the end of time. When .ACC=.PRE, shouldn't the .DN transition to a "1", which should cause the XIO tag REGEN_COMPLETE.DN to go true and stop that rung? Taking a guess at it, I believe the transition is happening so quickly the processor isn't seeing the change, therefore leaving it in this current state, unless all the Stars and Planets line up with the Sun and it changes the .DN bit at just the right time. Am I close? Thank you.