I am attempting to map registers from N10 in Micrologix 1400, to Modbus addresses at a customer’s PLC, over an Ethernet connection. All the registers I need to map are from file "N10". I need to send N10:00 through N10:58 from my Micrologix.

My PLC is the slave and the customer’s PLC (by G.E.) is the master. The customer's PLC will be reading registers from my PLC; I have no intention of reading registers from their PLC.

My customer gave me a list of how each Allen Bradley address should be mapped to each Modbus address. I.e. N10:00/00 shall be mapped to 40001.0, N10:00/01 to 40001.1, etc.

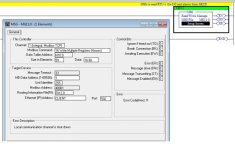

I created a MSG (see attached picture) in my program. I am not sure if I configured correctly? Not sure if there are any conditions I should predicate this MSG? I notice when I go online the "ER" bit is active - perhaps because the other PLC isn't on the network and it can't communicate?

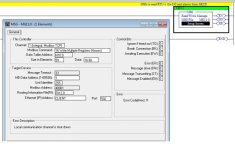

Also performed the setup in the channel configuration (see attached pictures). Not sure if this is correct?

I want to test my messaging before I send the PLC in the field so I'm convinced it actually is sending the registers that I desire. Someone told me I could use a program called Modbus Poll to check to see if the registers are coming across (Modbus Poll gives you a 30 day trial). I tried downloading this and "connecting" and didn't have any luck connecting...not sure why. Has anyone used this or similar program to check Modbus connection?

THANKS in advance! First timer working with Modbus messaging! I hope someone can help me here so I don't dread having to do it in the future

My PLC is the slave and the customer’s PLC (by G.E.) is the master. The customer's PLC will be reading registers from my PLC; I have no intention of reading registers from their PLC.

My customer gave me a list of how each Allen Bradley address should be mapped to each Modbus address. I.e. N10:00/00 shall be mapped to 40001.0, N10:00/01 to 40001.1, etc.

I created a MSG (see attached picture) in my program. I am not sure if I configured correctly? Not sure if there are any conditions I should predicate this MSG? I notice when I go online the "ER" bit is active - perhaps because the other PLC isn't on the network and it can't communicate?

Also performed the setup in the channel configuration (see attached pictures). Not sure if this is correct?

I want to test my messaging before I send the PLC in the field so I'm convinced it actually is sending the registers that I desire. Someone told me I could use a program called Modbus Poll to check to see if the registers are coming across (Modbus Poll gives you a 30 day trial). I tried downloading this and "connecting" and didn't have any luck connecting...not sure why. Has anyone used this or similar program to check Modbus connection?

THANKS in advance! First timer working with Modbus messaging! I hope someone can help me here so I don't dread having to do it in the future