JTPLC

Member

Hi All,

I currently have an intermittent issue on a CompactLogix 1769-L30ERM with firmware 28.11. When I get to the machine, all conditions for automatic running are true and it looks as if the machine is in sequence.

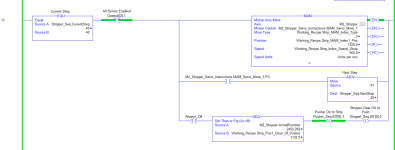

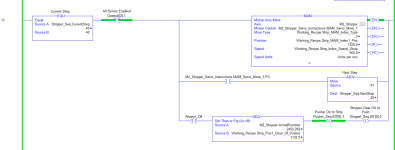

When looking in the program the next rung in the sequence is a motion axis move instructions. The conditions are true and the EN flag is true. However the move never starts its movement and the IP or DN flags never become true (pictured). I can move the servo with a motion direct command and use the position and speed of the MAM instruction and it moves as it should.

The only way I can seem to clear the issue is to drop power and reinstate.

I am under the suspicion it may be a bug in the firmware, does anyone know of this issue?

Thanks

I currently have an intermittent issue on a CompactLogix 1769-L30ERM with firmware 28.11. When I get to the machine, all conditions for automatic running are true and it looks as if the machine is in sequence.

When looking in the program the next rung in the sequence is a motion axis move instructions. The conditions are true and the EN flag is true. However the move never starts its movement and the IP or DN flags never become true (pictured). I can move the servo with a motion direct command and use the position and speed of the MAM instruction and it moves as it should.

The only way I can seem to clear the issue is to drop power and reinstate.

I am under the suspicion it may be a bug in the firmware, does anyone know of this issue?

Thanks