Trying to keep this response as short as possible...

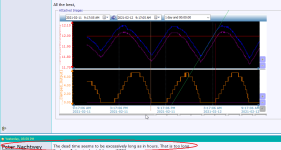

The Original Poster (OP) provided a lot of good information to start this thread: A trend of the closed-loop response showing the Process Variable (PV), temperature, and Control Variable (CV), valve percent, along with a general description of the process. The controller type [PID], form [PIDE, Dependent Gains], and gain values corresponding to the trend [P=5, I=8, D=1.5] were specified. This is all good, but not ideal for directly computing controller gains to improve performance.

It would be better to have open loop (manual mode) step response trends at one or more valve operating points under disturbance-free conditions. That may not be practical, especially with the apparently long process lag, or even allowable to run in manual mode for long periods of time considering policy, safety, product quality. However, there is enough insight available from the process description and the closed-loop response to make directional moves for controller tuning. One approach to working with the information at hand it to estimate process characteristics and use a tuning strategy (e.g., IMC-based) to compute gains for a desired response.

A very important point, brought up in this thread and others, is that the form of the PID equation in the controller and its engineering units for gains must be known. It may be necessary to convert the computed gains into compatible controller gains; such as whether the form is dependent or independent, and time-related gains are in terms of minutes, seconds, and/or inverse time. The OP specfied almost everything necessary in this regard by stating PIDE-dependent gains. In the context of trend charts showing temperature in degrees and controller output in percent, the missing piece is engineering unit (EU) scaling. This is because Allen-Bradley ControlLogix and PLC-5 (but not SLC) PID instructions expect "unitless" proportional gain, meaning it is in terms of percent-in-over-percent-out. So the PVEUMin and PVEUMax must be applied to EU-computed P gain to convert from temperature to percent. (Technically the same on the CV side, but this is typically in percent, zero to 100, already.)

In the OP's case it turns out the PVEUMin and PVEUMax are also zero to 100, meaning no extra conversion is needed on computing the P gain for PIDE, based on a process gain computed as degrees-per-percent. While this is convenient from a tuning standpoint, it does limit the controller's input range to between zero and 100 degrees.

A couple other follow-up pieces of information from the OP include valve type (ball valve), presence of valve stiction leading to intentional 1% output resolution, and a programmed deadband.

Using all of the OP's information thus far, an effectively tuned PI controller should be sufficient to maintain PV to target with a signficantly tighter tolerance than the current closed-loop oscillation. The disclaimers being: the trend chart only shows a snapshot in time over a relatively small operating window without set point changes or any apparent external disturbances. Nor does it show manual mode operation that may indicate a disturbance causing the oscillation.

All that said, plus previous discussion, the closed-loop behavior implies too much integral and not enough proportional action. IMC-based guidance is to use the process time constant for the integral term with dependent gains in the absence of significant pure deadtime. That is the motivation to increase from 8 minutes to a larger value estimated from the closed-loop response. One could try the phase shift time (~120 minutes) as a starting point, or maybe less if there is concern with such a large change.

On the gain side, I compute an amplitude ratio (AR) of about 0.036 (12.1-11.85/7) at the closed-loop frequency. As noted earlier with the PVEU settings this is already unitless for the A-B PIDE block. Conservative IMC guidance, with no deadtime, is to set P gain at 2 divided by process gain (Kp). If the AR is a good estimate of Kp, that would suggest a P gain up around 100. Since the AR could be attenuated, and that is 20x current P gain, a smaller increase is advised to start with. However, it does need some increase in proportional along with any de-tuning of the integral action, or the loop will become very sluggish or non-responsive.

In summary, one or more open-loop step response tests, up and down, will provide more definitive information than what is inferred from the closed-loop snapshot. In the absence of that, a starting point for incremental tuning is to increase P action and decrease I action. Half way to some IMC-based estimates for the configured PIDE is P=50, I=60, D=0, zero deadband. It would be advantageous to eliminate root cause of the valve stiction and/or reduce the step interval to a smaller effective value (e.g., 0.75% or 0.5%). If these changes improve performance, but short of expectation, make another increment. If possible, force a disturbance or set point change to observe response.

Adding complexity such as feedforward or other features would only be necessary if you are measuring disturbances and want controller action before they affect the PV, or if the deadtime is more significant than implied, or the process operating window moves, or there is asymmetric response or non-linearities. It will take explicit testing to look for these complicating factors, and the best-tuned PI is not meeting performance requirements.