Hi, If I may chime in...

Wiktor, I'm glad you realised that Ethernet is the best way to communicate between these 2 devices and are now up & running. I too use ML1400's with HMISTU655's & HMISTU855's, nice HMI.

Having read the thread, I felt it needed closure.

This is to assist others who may want, or have to use either DH485 or DF1 for ML1400 CH2(D-SUB9) to COM1(RJ45) on a HMISTO/STU & need to make a cable. It's not difficult, if you follow Schneiders driver help docs carefully, but some may get confused between the many wiring options they give as to which one to use. There is a little bonus too.

It's fairly comprehensive, so if someone feels this should be a "How To" posted somewhere else, please move it or ask me to post it seperately instead.

I had originally tried the ML1400 with the lesser, serial only, HMISTO511. Initially I used DH485 for that setup and made my own cable from the driver help file doc.

DH485 Cable: (ML1400 Ch2 D-SUB9>HMISTO/STU COM1 RJ45)

Page 14 of Schneiders "Allen-Bradley DH485 Duplex Driver" doc (attached below) shows the wiring options for COM1(RJ45) as RS-232C or RS-232C.

The top pinout is indeed RS-232C, but the bottom pinout is RS-422/485, it's a typo error. We are using RS-232C here.

So from this we use pin 1-RD(RXD), pin 2-SD(TXD) & pin 8-GND.

Now go to page 16. Here we use "b.Connection Diagram". Notice the CS/RS link on the target side & the note below. Ignore this link for STO/STU's, as it is only relevant to higher model Magelis HMI that have D-SUB9 COM ports.

In this diagram they do not show pin numbers on the target side as it relates to many different HMI models, which differ in port types & pinout numbering.

For reference, write "8" beside "GND", "2" beside "SD(TXD)" & "1" beside RD(RXD).

This is important! The diagram shows the D-SUB9 plug wiring intended for a NET-AIC. The ML1400 can connect directly to the HMI, if you don't have a NET-AIC. However, Ch2 on the ML1400 is a non-isolated port. The NET-AIC's ports are electrically isolated from each other & so it provides protection against ground loops & voltage differences between the devices connected to it. Connect without NET-AIC at your own risk!

The D-SUB9 standard pinout diagram was linked by Wiktor earlier, so I wont attach it again.

Now you should be ready to make your cable.

Once cable is ready you have to setup your equipment port & driver settings.

Setup Ch2 on ML1400 for Driver: DH485, Baud: 19,200, Node Address: 1

(or whatever Node number your PLC is assigned on your network).

In your Vijeo Designer project scroll down to "IO Manager" & right click then "New Driver". Select Manufacturer "Rockwell Automation", then from left list choose "Allen-Bradley DH485, then from right list choose "DH485 MicroLogix". A new driver is created under "IO Manager" named "AllenBradleyDH48501 [ COM1 ]", double click this. In the Driver Configuration window set connection type: RS-232C, trans speed: 19,200 & node number: 2

(or whatever Node number your HMI is assigned on your network).

Now expand "AllenBradleyDH48501 [ COM1 ]" & you should see your equipment "DH485MicroLogix01". Double click & you get Equipment Configuration window. Set your PLC's node number here: 1 (or whatever).

Don't forget to select "DH485MicroLogix01" as the "Scan Group" for each variable you create(d) or they will not work.

Now you have configured your DH485 driver & equipment in Vijeo Designer ready for download to the HMI.

Once the RSLogix 500 & Vijeo Designer projects are loaded to the equipment, plug in the cable & test your comms status at the PLC. You should see the COMM 2 indicator on the LCD display on steady. Online, check the comms status & you should see messages sent/received totals are active for Ch2. If you have any I/O to the HMI panels, they should be active now also.

DF1 Cable: (Here comes the bonus!)

The DH485 cable will also work for DF1, so no need to make a second cable!

Only differences are:

Set ML1400 Ch2 for DF1 & setup the new DF1 driver in Vijeo. The default settings for both are fine.

Don't forget to change the "Scan Group" for variables to the DF1 driver.

When testing, the COMM 2 indicator on LCD display will blink when comms are active.

Note: DF1 will also work with or without NET-AIC.

Because I chose to test DH485 initially I hadn't read the driver help file for DF1. I just tried the DH485 cable for DF1 after DH485 had worked & DF1 worked first time. But when I saw your diagram from the DF1 help file Wiktor, I noticed something straight away!

sthompson wrote:

From the Diagrams you Posted, it would be easy to confuse the RXD, and TXD Pins.

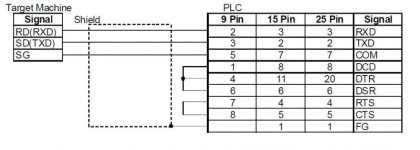

If I am understanding the Diagrams correctly, Pin 1 of the HMI (RXD) goes to Pin 3 of the PLC (TXD), Pin 2 of the HMI (TXD) goes to Pin 2 of the PLC (RXD), Pin 8 of the HMI (SG) goest to Pin 5 of the PLC (SG).

Is that the way you see it?

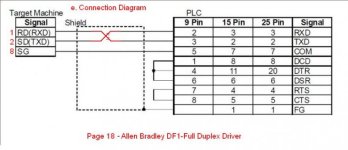

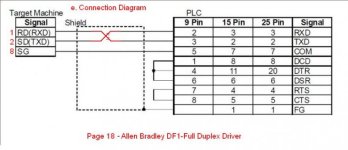

It would be even easier to confuse the RXD and TXD when the diagram is incorrect! Wiktor, you didn't answer the question as to how you saw it when you went to wire it up? If you followed Schneiders diagram it would never have worked as they show HMI pin1(RXD)> PLC pin2(RXD) & HMI pin2(TXD)> PLC pin3(TXD). Yet another typo. I've attached a corrected version of your earlier diagram. It's all academic beyond "The DH485 cable will also work for DF1, so no need to make a second cable!", but its always nice to get to the bottom of problems for everyone's benefit.

Geospark.