drbitboy

Lifetime Supporting Member

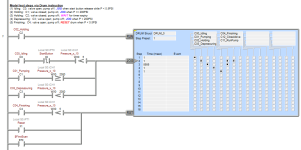

There is an instruction called a drum in AD software. Here it is in DoMore; I would think Click would be similar, but who knows. All it does is trade @parky's several [if step=N and (step N complete) then step = {step + 10}] sequence transition rungs for a behemoth of an instruction.

It does save a few rungs for setting outputs.

It does not have the pass-fail logic, and I am assuming the input raw WX0 16-bit integer is pressure in dPSI, so it will not be any shorter than @parky's in the end.

There is a bug when the DoMore simulator starts, in that for some reason C3 seems to start with an initial value of 1, which jogs the Drum to Step 2. I have not been able to figure out why, so if anyone can give me a hint; I am loathe to think it's a bug in the simulator.

But once the drum either completes a cycle or has been reset, then it runs as expected.

It does save a few rungs for setting outputs.

It does not have the pass-fail logic, and I am assuming the input raw WX0 16-bit integer is pressure in dPSI, so it will not be any shorter than @parky's in the end.

There is a bug when the DoMore simulator starts, in that for some reason C3 seems to start with an initial value of 1, which jogs the Drum to Step 2. I have not been able to figure out why, so if anyone can give me a hint; I am loathe to think it's a bug in the simulator.

But once the drum either completes a cycle or has been reset, then it runs as expected.