Thanks in advance to all who read this.

The PID I am looking at controls the injection of ozone into the water just before it goes into our filling machine.

Observations about original PID setpoints and the operation of the machine:

1. There is approximately 30 seconds between the time the PID calls for the generation of ozone and the sensor sees a change in ozone levels.

2. The flow of water in gallons per minute has an effect on the amount of the scaled error.

3. The ozone readings ranged from 0.015 PPM to 0.125 PPM.

Original PID setpoints are as follows:

1. P = 0.9

2. I = 0.3

3. D = 0

4. Loop update = 0.07

5. Max output CV% = 9

I have worked with the PID and made the following settings:

1. P = 0.9

2. I = 0.2

3. D = 1.50 (I set this high to try to make the PID respond sooner)

4. Loop update = 0.07

5. Set point before scale is 0.035 PPM.

6. I vary the max output based on the following flow amounts:

a. Flow less than 10 GPM, 0% max output

b. Flow between 11 to 50 GPM, 7% max output

c. Flow between 51 to 140 GPM, 8% max output

d. Flow greater than 141 GPM, 9% max output

If I can get my PID to be more steady, varying the max output may not be necessary.

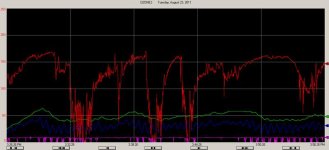

I have included an image of my PID setup screen and an image of a trend of the current PID settings:

1. Red line is water flow in GPM.

2. Green line is ozone level in intermediate tank.

3. Blue line is ozone level in supply line that feeds the intermediate tank.

4. Pink line is percent output from PID to ozone generator.

It appears that the output from the PID is occasionally staying on longer than necessary. I think this may be due to integral windup, but I could be wrong. Also, I just noticed that my feed forward bias is set at 15000, this may be a mistake that is adding to my strange readings.

I hope I have included enough information and I appreciate any advice you could give.

Thanks,

Tom W.

The PID I am looking at controls the injection of ozone into the water just before it goes into our filling machine.

Observations about original PID setpoints and the operation of the machine:

1. There is approximately 30 seconds between the time the PID calls for the generation of ozone and the sensor sees a change in ozone levels.

2. The flow of water in gallons per minute has an effect on the amount of the scaled error.

3. The ozone readings ranged from 0.015 PPM to 0.125 PPM.

Original PID setpoints are as follows:

1. P = 0.9

2. I = 0.3

3. D = 0

4. Loop update = 0.07

5. Max output CV% = 9

I have worked with the PID and made the following settings:

1. P = 0.9

2. I = 0.2

3. D = 1.50 (I set this high to try to make the PID respond sooner)

4. Loop update = 0.07

5. Set point before scale is 0.035 PPM.

6. I vary the max output based on the following flow amounts:

a. Flow less than 10 GPM, 0% max output

b. Flow between 11 to 50 GPM, 7% max output

c. Flow between 51 to 140 GPM, 8% max output

d. Flow greater than 141 GPM, 9% max output

If I can get my PID to be more steady, varying the max output may not be necessary.

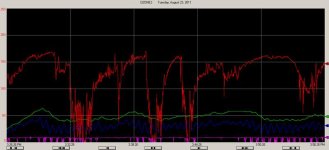

I have included an image of my PID setup screen and an image of a trend of the current PID settings:

1. Red line is water flow in GPM.

2. Green line is ozone level in intermediate tank.

3. Blue line is ozone level in supply line that feeds the intermediate tank.

4. Pink line is percent output from PID to ozone generator.

It appears that the output from the PID is occasionally staying on longer than necessary. I think this may be due to integral windup, but I could be wrong. Also, I just noticed that my feed forward bias is set at 15000, this may be a mistake that is adding to my strange readings.

I hope I have included enough information and I appreciate any advice you could give.

Thanks,

Tom W.