ganutenator

Lifetime Supporting Member

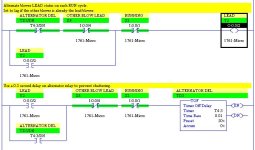

I need to figure out how to design Lead/Lag Logic between two Compressors. I have done this in the past with not too much difficulty. What makes this unique, is that there are two different PLC's. Also, because the Compressors are Vapor Recovery Units, one must be running at all times in order to not get fined by the state. So, when they switch Lead/Lag status, both will be need to be temporarily running.

Current Configuration:

Two SLC 5/04 PLC's with identical PLC programs connected via Data Highway Plus. One PLC per compressor.

Two identical Panel Views, each connected to their respected PLC via DH 485.

Conditions to Cause Switch

1) Loss of current running compressor.

2) Selection at either Panel View

3) Selection at HMI (Wonderware Screen)

4) Hours running greater than ?

5) etc. other suggestions accepted

Questions:

Should I use discrete I/O between the two PLC's for better results, or will the Data Highway + Network suffice.

There is existing code in one of the PLC programs to handle this, but it doesn't work. I would like to re-write that section from scratch, but am for some reason stumped. Too late in the day, Too many drugs as a kid, etc.?

Current Configuration:

Two SLC 5/04 PLC's with identical PLC programs connected via Data Highway Plus. One PLC per compressor.

Two identical Panel Views, each connected to their respected PLC via DH 485.

Conditions to Cause Switch

1) Loss of current running compressor.

2) Selection at either Panel View

3) Selection at HMI (Wonderware Screen)

4) Hours running greater than ?

5) etc. other suggestions accepted

Questions:

Should I use discrete I/O between the two PLC's for better results, or will the Data Highway + Network suffice.

There is existing code in one of the PLC programs to handle this, but it doesn't work. I would like to re-write that section from scratch, but am for some reason stumped. Too late in the day, Too many drugs as a kid, etc.?