AMarks95

Member

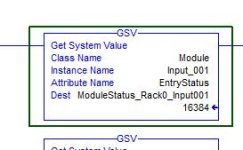

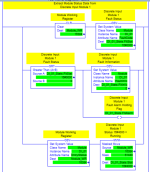

I've made a fault routine to notify operators when an IO module causes a major fault, and provided a button to manually reset the fault, but I'd like to be able to tell the operators exactly which module faulted.

(1769-L36ERM)

I've been referencing this PDF for creating the fault routine https://literature.rockwellautomation.com/idc/groups/literature/documents/pm/1756-pm014_-en-p.pdf

However, there's no information on what the "fault-specific" info DINT[8] values are. I'm thinking this might be able help me programmatically determine which module has faulted. Has anyone had experience with this?

(1769-L36ERM)

I've been referencing this PDF for creating the fault routine https://literature.rockwellautomation.com/idc/groups/literature/documents/pm/1756-pm014_-en-p.pdf

However, there's no information on what the "fault-specific" info DINT[8] values are. I'm thinking this might be able help me programmatically determine which module has faulted. Has anyone had experience with this?

Last edited: