RRoc

Member

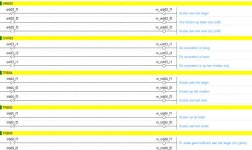

I want to Alias a dot members from a user defined to an array of different numbers. Since this can't happen what is more efficient a COP or MOV instruction.

Cop instruction for example COP Array[10].0 to Gen.Run or a MOV Array[10].0 to Gen.Run?

Cop instruction for example COP Array[10].0 to Gen.Run or a MOV Array[10].0 to Gen.Run?