Hi folks,

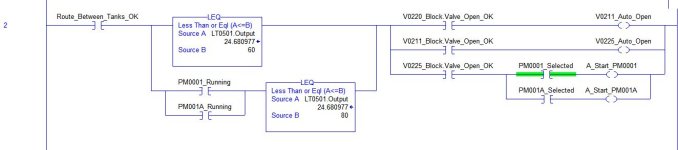

I have a piece of code from my first project that I'm looking to improve a bit so am looking for some advice on how to do so. There's just one rung at the moment which is pretty simple; the level in the tank reaches 60%, 2 valves open provided the safety valve is open, one of the two pumps is latched on until the level reaches 80% then the valves close and the pump stops.

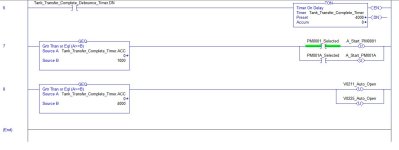

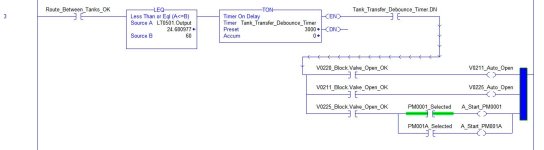

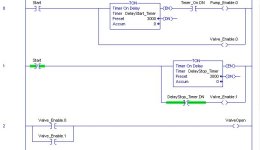

The reason I'm trying to improve it is because the valves and pump close and stop at the same time. This is only a 1" line so not much pressure or flow in the pipe but still. The first picture attached is the way it is currently and the second and third pictures are the proposed improvements. I try and avoid latch and unlatch bits if I can but I think it works here.

I haven't asked for advice on ladder logic before (I think anyway) so it would be interesting to see how other people would go about, what if any best practices you have to adhere to, can you see any issues with the improved version etc. I'm having one of those days where I'm just second guessing myself.

Thanks,

Darren

I have a piece of code from my first project that I'm looking to improve a bit so am looking for some advice on how to do so. There's just one rung at the moment which is pretty simple; the level in the tank reaches 60%, 2 valves open provided the safety valve is open, one of the two pumps is latched on until the level reaches 80% then the valves close and the pump stops.

The reason I'm trying to improve it is because the valves and pump close and stop at the same time. This is only a 1" line so not much pressure or flow in the pipe but still. The first picture attached is the way it is currently and the second and third pictures are the proposed improvements. I try and avoid latch and unlatch bits if I can but I think it works here.

I haven't asked for advice on ladder logic before (I think anyway) so it would be interesting to see how other people would go about, what if any best practices you have to adhere to, can you see any issues with the improved version etc. I'm having one of those days where I'm just second guessing myself.

Thanks,

Darren