Hello,

Its my first time working a project that involves PLCs. I need to develop a way to track parts with serial numbers that are passing through a conveyor. The tricky part is that it is a cyclical conveyor. The parts may stay on the conveyor for more than one cycle before they are picked up to be moved to the next part of the process. I have 18 nests and I need to keep track of their position and of what part is loaded on the nest (if any). I will also be tracking the picked up parts. There will only be a sensor where parts are loaded and picked up (specific nest locations).

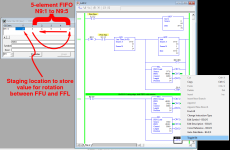

So far I am looking at shift registers to keep track of the loaded nests in the conveyor. Each bit in the shift register would be a specific nest location. However, ideally the shift register would not wipe the bit in the last position after an indexation, it would place that bit in the first bit of the shift register. Is this possible? Also, is there a way to clear specific bits in the shift register, instead of resetting the whole register? Is there another way to do this that I desire? Perhaps the solution is not exactly a shift register, but something more advanced. The other issue I have is how do I relate the bit in the shift register with the part ID. Any help is greatly appreciated.

Its my first time working a project that involves PLCs. I need to develop a way to track parts with serial numbers that are passing through a conveyor. The tricky part is that it is a cyclical conveyor. The parts may stay on the conveyor for more than one cycle before they are picked up to be moved to the next part of the process. I have 18 nests and I need to keep track of their position and of what part is loaded on the nest (if any). I will also be tracking the picked up parts. There will only be a sensor where parts are loaded and picked up (specific nest locations).

So far I am looking at shift registers to keep track of the loaded nests in the conveyor. Each bit in the shift register would be a specific nest location. However, ideally the shift register would not wipe the bit in the last position after an indexation, it would place that bit in the first bit of the shift register. Is this possible? Also, is there a way to clear specific bits in the shift register, instead of resetting the whole register? Is there another way to do this that I desire? Perhaps the solution is not exactly a shift register, but something more advanced. The other issue I have is how do I relate the bit in the shift register with the part ID. Any help is greatly appreciated.