Phillyblunz

Member

Hello everybody! I'm new here so let me know if there is a way to find this stuff already.

I am working with a PLC program and the customer wants to change from DNet to MODBUS for communication between the PLC and Multiranger 100.

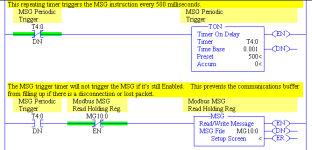

I am trying to set up the MSG blocks to make this work and was hoping for a bit better guide then the 1400 ref manual.

Basically how many files do I setup in the PLC if I only require a single reading from a single device?

A MSG block I know, but what about EQU and MOV blocks? Do I need them to get the reading from the Miltronics?

All I want to do is take the measured water level via MODBUS and place it in a data table.

The DNet setup somehow got the reading from a non-existant analog register.

Then it used a MOV block to place the level reading where the normal analog reading gets moved too, this gave redundancy if the DNet failed.

Now they want me to remove the analog altogether and only use MODBUS with no redundancy.

Tell me what else I need to tell you guys so you can help me out a bit.

So far I have created a program file called "LAD 9 - MODBUS"

Within I have a single rung with a MOV block on it.

I have setup a Data file called "MG10 - MODBUS"

Within the MG10 - MODBUS file is a series of parameters and it seems the only option is a binary entry of all data from here on out.

I am unsure of these parameters settings.

What is the easiest way to get the reading via MODBUS to the PLC?

Cheers!!

I am working with a PLC program and the customer wants to change from DNet to MODBUS for communication between the PLC and Multiranger 100.

I am trying to set up the MSG blocks to make this work and was hoping for a bit better guide then the 1400 ref manual.

Basically how many files do I setup in the PLC if I only require a single reading from a single device?

A MSG block I know, but what about EQU and MOV blocks? Do I need them to get the reading from the Miltronics?

All I want to do is take the measured water level via MODBUS and place it in a data table.

The DNet setup somehow got the reading from a non-existant analog register.

Then it used a MOV block to place the level reading where the normal analog reading gets moved too, this gave redundancy if the DNet failed.

Now they want me to remove the analog altogether and only use MODBUS with no redundancy.

Tell me what else I need to tell you guys so you can help me out a bit.

So far I have created a program file called "LAD 9 - MODBUS"

Within I have a single rung with a MOV block on it.

I have setup a Data file called "MG10 - MODBUS"

Within the MG10 - MODBUS file is a series of parameters and it seems the only option is a binary entry of all data from here on out.

I am unsure of these parameters settings.

What is the easiest way to get the reading via MODBUS to the PLC?

Cheers!!