Hi guys. Really fan of this forum but never posted anything, created the account just for this, no hate please

So, I'm working on a project with an S7-1200 with a Beijer HMI..

Everything kinda good until today, i was able to set/reset/exchange data through IsoTcp communication.

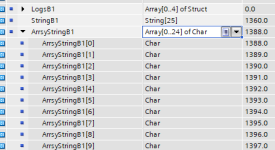

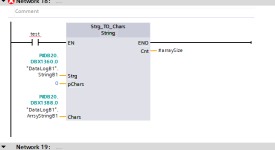

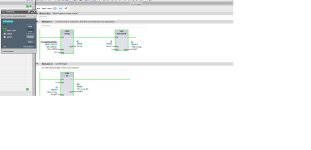

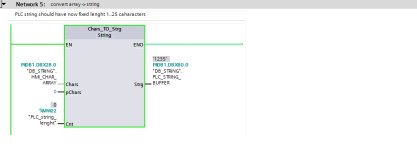

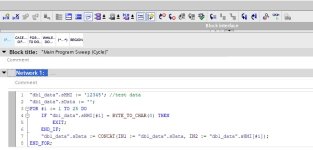

But now i need to exchange some plc string variables to display in the HMI, and also receive in the PLC the result of some input in the HMI ( as string, too).

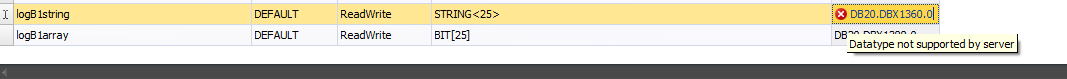

I tried to create Tags in the iX developer project (v2.4) but they only work as internal, i cannot set the plc datablock address the same way i do for int/bool etc..

Any clue on how to do it? I'm proficient in C#, but bits&bytes are rusty these days..

Thank you!

So, I'm working on a project with an S7-1200 with a Beijer HMI..

Everything kinda good until today, i was able to set/reset/exchange data through IsoTcp communication.

But now i need to exchange some plc string variables to display in the HMI, and also receive in the PLC the result of some input in the HMI ( as string, too).

I tried to create Tags in the iX developer project (v2.4) but they only work as internal, i cannot set the plc datablock address the same way i do for int/bool etc..

Any clue on how to do it? I'm proficient in C#, but bits&bytes are rusty these days..

Thank you!