We have a vacuum pressure sensor that has become faulty, unfortunately the original is obsolete but the manufacturer has supplied us with the replacement (these are manufactured by Festo). when the new sensor is fitted to the machine it is displaying a pressure of 145mBar on the HMI screen, this is when the machine is at rest and no vacuum is being generated. when the pressure sensor is disconnected from the analogue input 0v can be measured on the output, which correctly tracks the vacuum down to -1Bar, giving 10v output. if we measure the voltage on the analogue input card with the sensor disconnected we measure 2.3V.

we thought our new sensor may have been faulty but we have swapped it to a different machine and get the same results. this led us to think it may not be compatible, even though Festo assured us it is the correct unit, so we contacted the machine manufacturer. They have confirmed that we should only need to set the unit as 0-10V as the output type. This was already set correctly.

The old type sensor that was removed from our second machine was connected to the first machine and the readings are all correct on the HMI.

Can anyone suggest a way to resolve our issue or give us some checks to carry out?

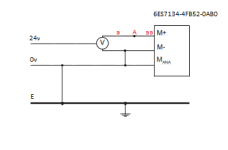

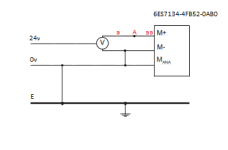

I have attached an image of the input connection details for the machine.

The input card is a Siemens 6ES7134-4FB52-0AB0 which is located in an ET200 remote rack.

we thought our new sensor may have been faulty but we have swapped it to a different machine and get the same results. this led us to think it may not be compatible, even though Festo assured us it is the correct unit, so we contacted the machine manufacturer. They have confirmed that we should only need to set the unit as 0-10V as the output type. This was already set correctly.

The old type sensor that was removed from our second machine was connected to the first machine and the readings are all correct on the HMI.

Can anyone suggest a way to resolve our issue or give us some checks to carry out?

I have attached an image of the input connection details for the machine.

The input card is a Siemens 6ES7134-4FB52-0AB0 which is located in an ET200 remote rack.