Hello,

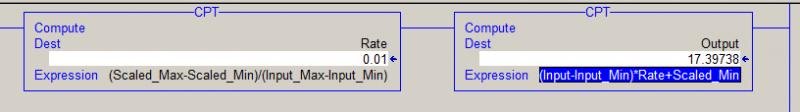

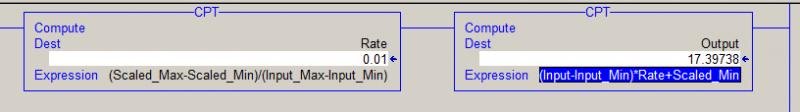

I am seeing an issue with inaccurate tank level. It is an elliptical bottom tank with an Anderson Level sensor mounted on the bottom of the tank. What is the proper determination of the level of fluid in this tank based on the 4ma-20ma signal from the sensor? For now we're doing a linear scaling which would work for the application. What would be the linear and non-linear level determination of the tank ? the current AOI is doing the math in the attached picture; Is this even accurate for linear ?

Thanks

I am seeing an issue with inaccurate tank level. It is an elliptical bottom tank with an Anderson Level sensor mounted on the bottom of the tank. What is the proper determination of the level of fluid in this tank based on the 4ma-20ma signal from the sensor? For now we're doing a linear scaling which would work for the application. What would be the linear and non-linear level determination of the tank ? the current AOI is doing the math in the attached picture; Is this even accurate for linear ?

Thanks