Ben Mattison

Member

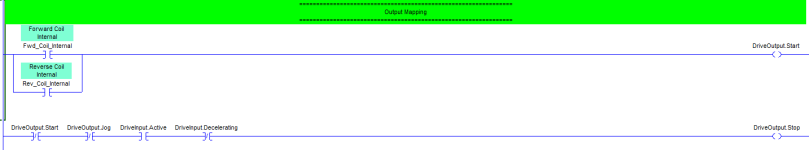

Normally when writing to the PF525 over ethernet i use the active bit in the stop command as told to do so by many.

this is fine for most applications however. this means the drive has to ramp down and fully stop before start can be processed again.

is there a way of starting the drive while its still active and ramping down.

my application is a conveyor system that indexes and counts products onto a conveyor using a photocell.

when blocked it adds 1 to count and tell the next conveyor to run until photocell is clear. once count is full the conveyor holding the full batch of product runs off.

what im finding is because im waiting for the ramp down the next product catches up and after this happening a few times the products are back to back and i loose the gap for my count.

i have got around this by leaving the drive running at 0hz and switching to 50hz when told to run.

not convinced this is good practice running a drive at zero frequency?

this is fine for most applications however. this means the drive has to ramp down and fully stop before start can be processed again.

is there a way of starting the drive while its still active and ramping down.

my application is a conveyor system that indexes and counts products onto a conveyor using a photocell.

when blocked it adds 1 to count and tell the next conveyor to run until photocell is clear. once count is full the conveyor holding the full batch of product runs off.

what im finding is because im waiting for the ramp down the next product catches up and after this happening a few times the products are back to back and i loose the gap for my count.

i have got around this by leaving the drive running at 0hz and switching to 50hz when told to run.

not convinced this is good practice running a drive at zero frequency?