Greetings!

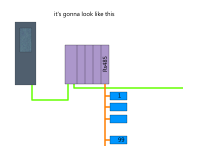

S7-1500, TIA portal.

There's a need to control a few peripheral devices(smart sensors).

A command 'Out_1' says to device 1 "give output"

A command 'Out_2' says to device 2 "give output"

A command 'Out_3' says to device 2 "give output"

.

.

.

A command 'Out_99' says to device 99 "give output"

and again,

A command 'Out_1' says to device 1 "give output"

A command 'Out_2' says to device 2 "give output"

A command 'Out_3' says to device 2 "give output"

.

.

.

A command 'Out_99' says to device 99 "give output"

At the moment I have on my bench only two sensors for testing.

The current longest cycle time of PLC is about 12ms.

I'm afraid that such a bunch of polling peripheral devices just causes a wild slowing down of plc cycle.

My question is, perhaps anyone knows a technique how to do that by a proper way or more optimized way.

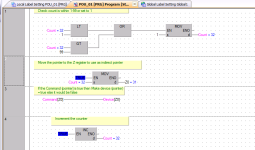

And generally is there a way to distribute the commands between plc scans (cycles)? So to speak, not to do that at a single scan.

BR

S7-1500, TIA portal.

There's a need to control a few peripheral devices(smart sensors).

A command 'Out_1' says to device 1 "give output"

A command 'Out_2' says to device 2 "give output"

A command 'Out_3' says to device 2 "give output"

.

.

.

A command 'Out_99' says to device 99 "give output"

and again,

A command 'Out_1' says to device 1 "give output"

A command 'Out_2' says to device 2 "give output"

A command 'Out_3' says to device 2 "give output"

.

.

.

A command 'Out_99' says to device 99 "give output"

At the moment I have on my bench only two sensors for testing.

The current longest cycle time of PLC is about 12ms.

I'm afraid that such a bunch of polling peripheral devices just causes a wild slowing down of plc cycle.

My question is, perhaps anyone knows a technique how to do that by a proper way or more optimized way.

And generally is there a way to distribute the commands between plc scans (cycles)? So to speak, not to do that at a single scan.

BR

Last edited: