Help will be Rewarded in the future I promise

Good evening everyone

I 'm working on a personal project, hope someone would be so kind and could help me providing some information/guidance on this subject

I want to make automation using Raspberry and a PLC

I got a recommendation to use Wago combined with raspberry because this PLC brand has a driver called Codesys that helps to connect Raspberry Pi3 with the PLC, I found a lot of tutorials about it involving MQTT, Node-Red and others; since I'm not very familiar with Raspberry yet, it's been tough to pick one or other way of communication to read/write information from/to Wago PLC

Another inconvenient I have is the budget, Wago is a little bit more expensive than other PLCs, since it's a project with lots of i/o(s), scaling this project to something bigger would cost me a lot, so I was thinking of using Siemens 1200 PLC(SIMATIC CPU 1214C) instead

Another option I was thinking of is using the ET200 SP CPU module, if I use it I was told it wasn't necessary to buy the SIMATIC CPU 1214C PLC, besides the I/O Modules are cheaper than regular I/O modules for the ET200 SP than for the 1214 CPU, ET200 provides up to 32 i/o modules, I don't know if RPI3, MQTT/Node-Red are compatible with only ET200 SP with no use of another PLC

I found on youtube videos about S7-1200 been compatible with raspberry using Snap7 Phyton, MQTT/Node-Red as well, S7 been compatible with Java and C# and sharp 7 libraries, different OPC types, so the list is so long that I can't even imagine

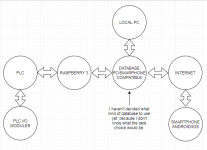

I attach an image of the scheme I'd like to use for the network architecture

Hope someone please could give me some advice

Thanks in advance

Best regards

https://imgur.com/rr1OVyE

Good evening everyone

I 'm working on a personal project, hope someone would be so kind and could help me providing some information/guidance on this subject

I want to make automation using Raspberry and a PLC

I got a recommendation to use Wago combined with raspberry because this PLC brand has a driver called Codesys that helps to connect Raspberry Pi3 with the PLC, I found a lot of tutorials about it involving MQTT, Node-Red and others; since I'm not very familiar with Raspberry yet, it's been tough to pick one or other way of communication to read/write information from/to Wago PLC

Another inconvenient I have is the budget, Wago is a little bit more expensive than other PLCs, since it's a project with lots of i/o(s), scaling this project to something bigger would cost me a lot, so I was thinking of using Siemens 1200 PLC(SIMATIC CPU 1214C) instead

Another option I was thinking of is using the ET200 SP CPU module, if I use it I was told it wasn't necessary to buy the SIMATIC CPU 1214C PLC, besides the I/O Modules are cheaper than regular I/O modules for the ET200 SP than for the 1214 CPU, ET200 provides up to 32 i/o modules, I don't know if RPI3, MQTT/Node-Red are compatible with only ET200 SP with no use of another PLC

I found on youtube videos about S7-1200 been compatible with raspberry using Snap7 Phyton, MQTT/Node-Red as well, S7 been compatible with Java and C# and sharp 7 libraries, different OPC types, so the list is so long that I can't even imagine

I attach an image of the scheme I'd like to use for the network architecture

Hope someone please could give me some advice

Thanks in advance

Best regards

https://imgur.com/rr1OVyE