dbh6

Lifetime Supporting Member

Hello all,

PLC is a AB control logix 1756-L62 processor

Analog Input Card is a 1756 IF6I

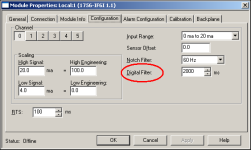

I configured the card for a 4-20ma signal and scaled it to engineering units. So now I'm trying to filter an analog signal using ladder logic. For example the scaled analog data is in real format,so on the HMI (FT View SE) im displaying the analog signal with 2 decimal digits (customers request), so say my analog reading read a scaled value of 12.35, depending on the process those decimal digits can fluctuate like 12.33,12.32,12.28 etc. So what im trying to do is filter this signal so it does not fluctuate as much. I know their is a standard way of doing this such that you take the raw data and multiply it by 0.9(which is called the weight) and multiply the raw data with 1.1 ???? it was something of that sort but i don't recall the correct steps, so if anyone can explain how to do this with an explanation i would appreciate it. My whole goal, is once i know how to filter it, is to create an add on instruction for it.

???? it was something of that sort but i don't recall the correct steps, so if anyone can explain how to do this with an explanation i would appreciate it. My whole goal, is once i know how to filter it, is to create an add on instruction for it.

PLC is a AB control logix 1756-L62 processor

Analog Input Card is a 1756 IF6I

I configured the card for a 4-20ma signal and scaled it to engineering units. So now I'm trying to filter an analog signal using ladder logic. For example the scaled analog data is in real format,so on the HMI (FT View SE) im displaying the analog signal with 2 decimal digits (customers request), so say my analog reading read a scaled value of 12.35, depending on the process those decimal digits can fluctuate like 12.33,12.32,12.28 etc. So what im trying to do is filter this signal so it does not fluctuate as much. I know their is a standard way of doing this such that you take the raw data and multiply it by 0.9(which is called the weight) and multiply the raw data with 1.1