Ooops, of course Lancie1 is correct on the cable size. So much for memory.

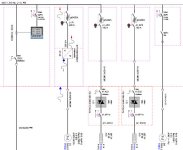

The SCA number is the short circuit amps available. From what you've said, the utility provides almost 47KA. Running this through a quick calculator (that does NOT add in motor contribution), then at the switchgear you would have just under 45KA. At the MCC you would have about 33KA, and at the panel - assuming #1 AWG in conduit - you would have about 17KA.

NOTE - THESE NUMBERS ARE ROUGH ESTIMATES THAT DO NOT TAKE INTO CONSIDERATION MOTOR CONTRIBUTION OR THAT ALL LENGTHS ARE CORRECT.

If it were me, I would choose a 65KA breaker for the MCC and a 35KA breaker for the panel.

You could do 65KA for both, but cable impedance would severely limit the current going to your panel. If you don't have a lot of large motors, then the motor contribution shouldn't be enough to increase the fault current much beyond the 17KA.

There are plenty of calculators out there to help do this. You need to understand what you are putting in for the numbers. I would suggest doing some reading on some of the websites about fault current calculations. There are some software packages that are available that your company should consider purchasing or hire a firm (like they did at the beginning) to help with some of this.

It is really sad that your company hasn't embraced arc flash safety.

Before you do too much, please read this article:

http://www.iaei.org/magazine/2012/03/arc-flash-a-survivors-perspective/

and watch these videos:

http://donniesaccident.com/

http://www.metacafe.com/watch/1555440/arc_flash_while_racking_a_breaker/

Then show them to your manager/boss and explain that you don't want to go home like that and neither should anyone else at your plant.

I am glad to hear that you want to do this right.