CaspianSage

Member

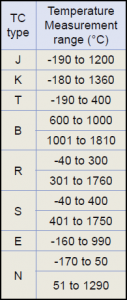

I have looked at several web sites and have gotten different ratings from almost all of them as to the temperature ranges of thermocouples.

Here is an example of two sites but there are others with different ratings than these. Some of the sites are stating the specs for the ones they sell but other sites are just providing data, not selling anything. So why the differences?

I understand that the type of material encasing the thermocouple makes a difference but some of these ranges are wildly different. Why do some say the lowest is zero degrees?

And Look at this if you want.. http://www.pyromation.com/Catalog/gen06.pdf

SITE 1 J

J

(0 to 760) °C

[32 to 1400] °F

Site 2 - J

Type J Temperature Range:

Type J Thermocouple Grade WireThermocouple grade wire, -346 to 1,400F (-210 to 760C)

-----------------------------------------------------------------------------------------------

Site 1 K

K

(0 to 1260) °C

[32 to 2300] °F

Site 2 K

Type K Temperature Range:

Type K Thermocouple Grade WireThermocouple grade wire, –454 to 2,300F (–270 to 1260C)

--------------------------------------------------------------------------------------------------

Site 1 T

T

(-200 to 370) °C

[-328 to 700] °F

Site 2 T

Type T Temperature Range:

Type T Thermocouple Grade WireThermocouple grade wire, -454 to 700F (-270 to 370C)

Here is an example of two sites but there are others with different ratings than these. Some of the sites are stating the specs for the ones they sell but other sites are just providing data, not selling anything. So why the differences?

I understand that the type of material encasing the thermocouple makes a difference but some of these ranges are wildly different. Why do some say the lowest is zero degrees?

And Look at this if you want.. http://www.pyromation.com/Catalog/gen06.pdf

SITE 1 J

J

(0 to 760) °C

[32 to 1400] °F

Site 2 - J

Type J Temperature Range:

Type J Thermocouple Grade WireThermocouple grade wire, -346 to 1,400F (-210 to 760C)

-----------------------------------------------------------------------------------------------

Site 1 K

K

(0 to 1260) °C

[32 to 2300] °F

Site 2 K

Type K Temperature Range:

Type K Thermocouple Grade WireThermocouple grade wire, –454 to 2,300F (–270 to 1260C)

--------------------------------------------------------------------------------------------------

Site 1 T

T

(-200 to 370) °C

[-328 to 700] °F

Site 2 T

Type T Temperature Range:

Type T Thermocouple Grade WireThermocouple grade wire, -454 to 700F (-270 to 370C)

Last edited: