Eric Nelson

Lifetime Supporting Member + Moderator

Re: Ken take a break

I'll second that request!... :nodi:

And along the same topic...

Is there some setting or "trick" to make RSLogix automatically open full screen without having to click "Maximize" each time it's started?... zzzzz

beerchug

-Eric

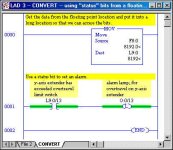

Peter Nachtwey said:To the RSLogix programmers:

RSLogix register file data windows should remember the size, columns and number format when the window is closed so that it will be restored to exactly the state as when the window is reopenned. Better yet would be to allow each word to be formated individually so that some can be in hex, others in decimal and others in binary. These suggestions would save much time of the users of RSLogix.

I'll second that request!... :nodi:

And along the same topic...

Is there some setting or "trick" to make RSLogix automatically open full screen without having to click "Maximize" each time it's started?... zzzzz

beerchug

-Eric