TheDude_Abides

Member

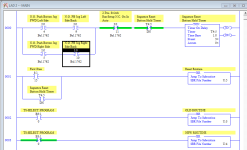

We have a shackle bender that has a ML1200 that was programmed from an outside contractor. Problem is we are in the middle of commissioning the equipment and we are having to do alot of stops in the middle of the process and restart. The programmer didnt account for this so we have to go through and flip all the limit switches for the PLC to think it has completed the process and it will restart the process. WHat would be the best way to use the Run/Setup switch to restart the process? The programmer used alot of latches, unlatches, and ONS's. That equipment runs fine unless you have to stop in the middle.

I've included the program in a compressed file. To me the program is very scattered and not organized. Hopefully someone can make heads or tail. I'm not asking for anyone to do my job for me but maybe just point me in the right direction.

I've included the program in a compressed file. To me the program is very scattered and not organized. Hopefully someone can make heads or tail. I'm not asking for anyone to do my job for me but maybe just point me in the right direction.