Hello everyone,

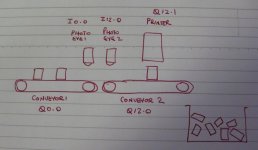

Question for you all: I’m working on an assignment for my future PLC students and need a realistic example system from industry. They will be wiring up Siemens S7-300 CPUs with a single 16 DI/DO module, then connecting this via Profinet to a Siemens ET200S IM-151 PN, with one digital input module and one digital output module. They will have 2 pushbuttons with LEDs, one to be wired into an input and output to the ET200S and one to the wired to an input and output on the DI/DO module of the S7-300. They will have already covered timers and counters, so I’m looking for an interesting sample system and assignment to give them. My initial thought was a pump driven by two pushbuttons, one on the main control cabinet and one on the machine itself. Then, maybe there’s a delay of 5 seconds or something before the pump switches off after the button (toggle) has been pressed to switch it off. We have enough 24V contactors for them to wire up 1 each also as part of the system, so this could be thrown in there too. I was thinking the LEDs would represent the pump, but they could represent something else altogether. In fact the system doesn’t have to have anything to do with a pump. Maybe one of the contacts from the contactor could be monitored and turn on an error bit if it is not properly energized. Just some ideas of the top of my head. I would like to introduce a common programming technique/condition that is often necessary for real systems.

Does anyone have an idea of a realistic example from a simple system that you may have worked on/programmed that I could use as an assignment? Would be very much appreciated.

Question for you all: I’m working on an assignment for my future PLC students and need a realistic example system from industry. They will be wiring up Siemens S7-300 CPUs with a single 16 DI/DO module, then connecting this via Profinet to a Siemens ET200S IM-151 PN, with one digital input module and one digital output module. They will have 2 pushbuttons with LEDs, one to be wired into an input and output to the ET200S and one to the wired to an input and output on the DI/DO module of the S7-300. They will have already covered timers and counters, so I’m looking for an interesting sample system and assignment to give them. My initial thought was a pump driven by two pushbuttons, one on the main control cabinet and one on the machine itself. Then, maybe there’s a delay of 5 seconds or something before the pump switches off after the button (toggle) has been pressed to switch it off. We have enough 24V contactors for them to wire up 1 each also as part of the system, so this could be thrown in there too. I was thinking the LEDs would represent the pump, but they could represent something else altogether. In fact the system doesn’t have to have anything to do with a pump. Maybe one of the contacts from the contactor could be monitored and turn on an error bit if it is not properly energized. Just some ideas of the top of my head. I would like to introduce a common programming technique/condition that is often necessary for real systems.

Does anyone have an idea of a realistic example from a simple system that you may have worked on/programmed that I could use as an assignment? Would be very much appreciated.