drbitboy

Lifetime Supporting Member

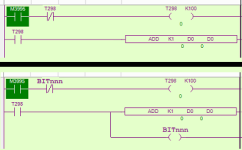

Yes it works, but there are simpler ways; see two examples below.hello again

basically what I wanted to find was a solution to increase a register (D) every 1 second

So, I combining a timer and a counter seems to be a good solution

The bottom approach below will certainly work. On some PLC brands, depending on the specifics of the internal TON implementation, the top approach might work as well.

BITnnn is a PLC-internal bit (discrete tag).

Caveat: with both your working approach and these simpler rungs, D0 will increment at intervals slightly greater than 1s, on average it will be 1s plus the mean scan cycle time,, probably between every 1.001s and 1.010s, possibly longer if the scan times are long.