drbitboy

Lifetime Supporting Member

Scratch that: I am not being trolled; I am (was) being dense.

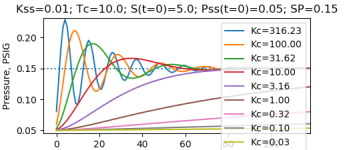

What Peter and Keith were so patiently trying to get through my t'ick skull is that, because it is a well-behaved, decaying non-integrating system in pressure (for which fan speed is a near-proxy), a proportional-only controller with PV=pressure and CV=dSpeed/dt (fan speed ramp) is equivalent to an Integral-only controller with PV=Pressure and CV=Speed.

A PID controller with very low (or zero) gain (proportional reaction) but not too much integral reaction will always get there, albeit slowly.

Thanks for your kindness!

What Peter and Keith were so patiently trying to get through my t'ick skull is that, because it is a well-behaved, decaying non-integrating system in pressure (for which fan speed is a near-proxy), a proportional-only controller with PV=pressure and CV=dSpeed/dt (fan speed ramp) is equivalent to an Integral-only controller with PV=Pressure and CV=Speed.

A PID controller with very low (or zero) gain (proportional reaction) but not too much integral reaction will always get there, albeit slowly.

Thanks for your kindness!

Last edited: