TheDude_Abides

Member

For some reason, I just cannot think of a solution to a problem concerning some basic ladder elements. I have tried thinking of the problem in a different context and still cannot come up with a solution. I am still a beginner.

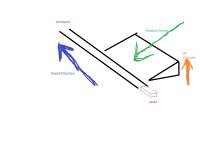

I have a laser with a windowed output that services a conveyor. The conveyor is loaded from the side with a pneumatic cylinder. The conveyor only runs while an operator is monitoring the process. So during breaks the machine is shut off, only to be started again 10 mins later.

If a product is on the conveyor then the solution is simple enough. The laser will initialize the solenoid and raise a platform via the cylinder. The cylinder will de energize and drop the product onto the conveyor when the previous product proceeds beyond the laser's windowed output. When the XIC that monitors the laser goes TRUE then an RTO counts 200 ms then de energizes the output, dropping the product onto the conveyor to start the process over. Simple enough.

My block is coming from when there is no product on the conveyor. I dont want the operator to have to place a product on the conveyor to get it to run. I just want the operator to approach the machine, hit START, no matter if the conveyor has a product in the window or not. I can get the cylinder to raise no problem but cannot get the cylinder to drop the product because there is no input to initialize the drop.

As I type this out it seems like a simple problem, and any other day, I should be able to solve this no problem. But for some reason, today is the day. Any help is greatly appreciated.

Info on the laser: The discreet windowed output is set for 500mm to energize and 750mm to denergize. It also has an analog output with a 0-10v ouput. Both provide information to the ML1400 simultaneously.

I have a laser with a windowed output that services a conveyor. The conveyor is loaded from the side with a pneumatic cylinder. The conveyor only runs while an operator is monitoring the process. So during breaks the machine is shut off, only to be started again 10 mins later.

If a product is on the conveyor then the solution is simple enough. The laser will initialize the solenoid and raise a platform via the cylinder. The cylinder will de energize and drop the product onto the conveyor when the previous product proceeds beyond the laser's windowed output. When the XIC that monitors the laser goes TRUE then an RTO counts 200 ms then de energizes the output, dropping the product onto the conveyor to start the process over. Simple enough.

My block is coming from when there is no product on the conveyor. I dont want the operator to have to place a product on the conveyor to get it to run. I just want the operator to approach the machine, hit START, no matter if the conveyor has a product in the window or not. I can get the cylinder to raise no problem but cannot get the cylinder to drop the product because there is no input to initialize the drop.

As I type this out it seems like a simple problem, and any other day, I should be able to solve this no problem. But for some reason, today is the day. Any help is greatly appreciated.

Info on the laser: The discreet windowed output is set for 500mm to energize and 750mm to denergize. It also has an analog output with a 0-10v ouput. Both provide information to the ML1400 simultaneously.

Last edited: