Greetings,

I am a complete NOOB but wanting to learn ladder logic, I have started a couple of on-line courses but I like to have a go to help me learn.

My setup is:

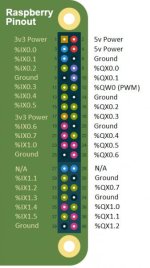

Raspberry Pi zero w

OpenPLC

AdvancedHMI

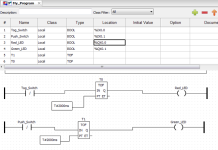

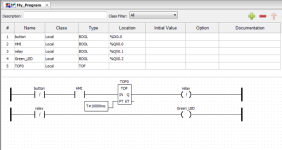

I have two switches and two LED's one red and one green and they are referenced in the ladder logic.

Switch is %IX0.0

Push switch is &Ix0.2

Red LED is %QX0.0

Green LED is %QX0.1

When I use the physical switches the LEDs light up as they are supposed to.

So I downloaded and installed Advanced HMI and I added two button and two LED's to match my real setup.

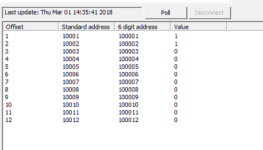

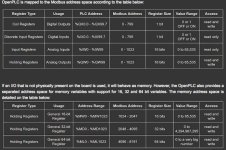

Using the address 00001 & 00002 the LED's light up on my monitor when I operate the physical switch... Great!

I cannot for the life of me though use the virtual on screen buttons to light the LED's

I have tried 10001 & 1001 as addresses but they just won't light. (infact 10001 just displays an error)

I have been at this now for a couple of days and have read lots of online docs but I just don't seem to be getting anywhere.

Could someone spell it out for me like you would a child lol.

Thanks in advance and sorry if this is not the right place

I am a complete NOOB but wanting to learn ladder logic, I have started a couple of on-line courses but I like to have a go to help me learn.

My setup is:

Raspberry Pi zero w

OpenPLC

AdvancedHMI

I have two switches and two LED's one red and one green and they are referenced in the ladder logic.

Switch is %IX0.0

Push switch is &Ix0.2

Red LED is %QX0.0

Green LED is %QX0.1

When I use the physical switches the LEDs light up as they are supposed to.

So I downloaded and installed Advanced HMI and I added two button and two LED's to match my real setup.

Using the address 00001 & 00002 the LED's light up on my monitor when I operate the physical switch... Great!

I cannot for the life of me though use the virtual on screen buttons to light the LED's

I have tried 10001 & 1001 as addresses but they just won't light. (infact 10001 just displays an error)

I have been at this now for a couple of days and have read lots of online docs but I just don't seem to be getting anywhere.

Could someone spell it out for me like you would a child lol.

Thanks in advance and sorry if this is not the right place

Last edited: