Differences SLC500/PLC5 off the top of my head:

IO bit adressing scheme: SLC 0-15 (decimal). PLC5 0-7 + 10-17 (octal).

File sizes: SLC max 256 words (0-255). PLC max 1000 words (0-999).

SCP (scale with parameters) instruction: Does not exist on PLC5.

Oneshot instructions: SLC "OSR". PLC "ONS" + "OSR" + "OSF". There are differences with regards to where the oneshots can be placed.

SLC hardware configures itself when you pick and place modules in "IO configuration".

PLC hardware needs to be set up with dipswitches in the chassis.

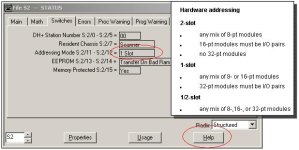

SLC IO adressing is straightforward as compared with the PLC5 because of the 2-slot, 1-slot, ½-slot adressing scheme. 2-slot utilises the available adress space best. ½-slot is most flexible.

SLC analog IO has fixed and straightforward adressing. PLC5 analog IO needs to be setup in the IO configuration AND needs to be updated with block transfers.

SLC ch 1 node adress and speed is set by software. PLC5 ch1A is set by dipswitches.

I think that an SLC5/04 is actually faster than a "classic" PLC5 processor.

edit: That PLC5/10 does not allow any remote chassis. So you are limited to max 16 IO modules (with an external power supply).

But you would be hard pressed to have more IO with only 6 k program memory to play around with.

Also, there is no EPROM, so check the date on the battery