Logixpro Dual Compressor

- Thread starter Aintbad

- Start date

Similar Topics

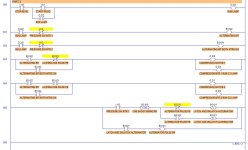

I am doing the Logixpro 500 simulator for exercise 2 using dual compressors. I can get the dual compressors to swap but am now needing to have...

Part 3 – Coping with Large Demands for Compressed Air

Your current program should be suitable for maintaining the desired pressure range as long...

Hello Forum Friends, I need help, I have to do the Dual compressor in [LogixPro], and the truth is that not how you use this program, please HELP...

First i would like to say that this is a grat site. I was viewing the thread on the Dual Compressor Simulation for Logixpro. I have run 150 mph...

Can anyone help me with the ladder logic of the logixpro simulations for the dual compressor.